The barrier properties of flexible packaging films are vitally important to ensure exceptional product quality and maximise shelf life. All our BOPP films demonstrate excellent moisture barrier.

Our Propafilm™ Strata range of mono structure films provide exceptional barrier to aroma, mineral oils and oxygen even at high relative humidity levels ensuring increased shelf life and reduced food waste.

Specific grades are also available with enhancements that provide additional barrier performance depending on the products needs.

For some markets superb clarity and gloss are pre-requisites to enhance on-shelf appeal. All our acrylic coated BOPP films offer excellent optical properties as well as superior packaging machine performance.

Included in this range are films with controlled shrink tightening properties that ensures a tight wrap, maximising the products appearance.

Our films with peelable seals enable easy opening of packs, ideal for consumers with reduced dexterity. The acrylic coating ensures a broad sealing range, which enables a wide packaging operating window and good machinability in all standard formats.

If you collate packs together for transit or multi packs, then our films for collation and bundle wrap will ensure that they do not stick to coextruded OPP films wrapping the individual pack.

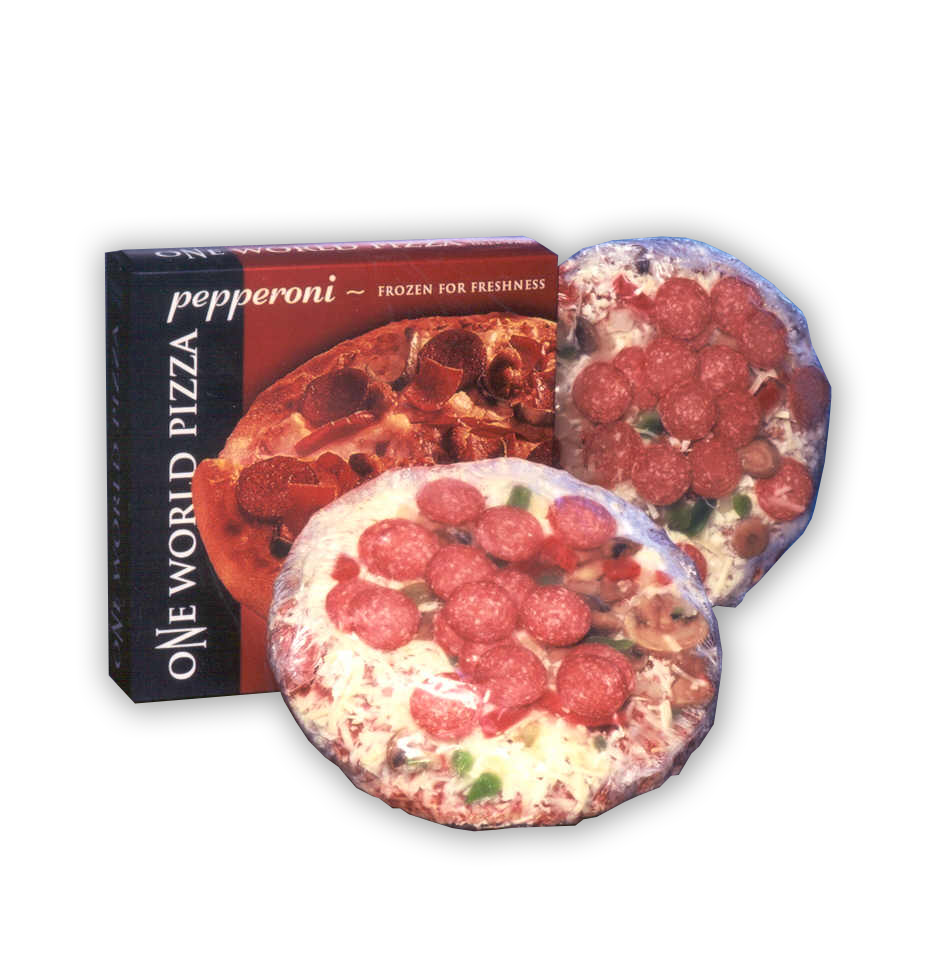

For frozen snacks and meals, coextruded films with wide seal ranges are ideal for the challenging packing and storage conditions.

Condensation can be an issue for many moist products, leading to poor pack appearance. Our anti-mist films minimises this issue. They have a proven record in vertical form fill and lamination applications.

Many products need protection to ensure they remain in optimum condition. Our BOPP films offer barrier performance against oxygen, aromas, moisture and mineral oils.

Propafilm™ HTD is the film of choice for frozen foods such as pizzas and paninis and other snacks. The very wide seal window on both surfaces, strong hot tack and a low COF have been designed especially for frozen food lines.

Shelf stable, “heat-and-eat” packs prefer the stability of in-mould labels. Choose gloss or soft touch surface to complete your branding.